If you’re into building large projects, you’ll eventually find yourself looking at wire rope. Multistrand steel wire used as antenna guy wires, bridge supports, and plenty of other uses. The [HowNot2] team tested an old rule of thumb for wire rope. “Never saddle a dead horse”.

Click through the break for more:

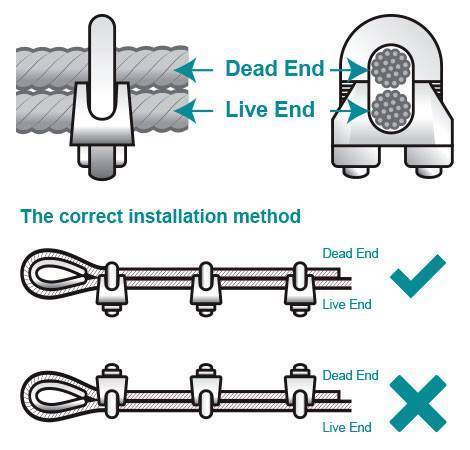

The old saying refers to the clips used on wire rope. These clips have a saddle, and u shaped bolt. As the diagram shows, the saddle side of the bolt should always go on the live (loaded) end of the cable, not the dead (cut) end. This is because the saddle has teeth to grip the cable, and protects it from crimping and damage over time.

[HowNot2] tests a number of different wire rope clamps – including improper installation. The best clamps are hydraulically crimped connectors. These require some expensive tooling — which is worth it when your life depends on the connection.

When testing got to the u-clips, saddling the live side went fine. When saddling the “dead horse”, the pull test failed at a lower force. Before the failure though, the joint made sounds that would instill fear in the heart of anyone who’s been around heavy equipment or cranes. The adage turns out to be true – never saddle a dead horse.

If you really want to know more about wire rope rigging, the US Navy has you covered.

Way back in the ’70’s, I worked painting watertowers around the Midwest. The quote “Don’t saddle a dead horse” was our mantra when rigging cables for access.

You mean using a piece of copper tubing and pounding it with a hammer is the WRONG way to make the loop at the end of the wire? Oh boy, I’ll be right back….

what if the horse was saddled before it died?! huh?

So when something is designed to be used in a particular way, if you use it in a way that is contrary to its design, it doesn’t work as well?

Shocking if true.

Were they designed, or was it a functional necessity and then people found out the hard way which is the correct orientation?

inquiring minds want to know

Yeah,

that one

I’m pretty certain and then just what’s left is figuring out the hard way on how NOT to install it.

The term was probably a pun on hawse, for hawser, a type of rope.

Good call. On ships and boats we always called the end of the line the “bitter end.” Then there was the working part and the standing part with respect to blocks etc. Never heard it called the “dead end” but with high-risk rigging and wire ropes, moving loads and other dangerous but necessary activities, I can see how that name would probably have earned itself many times over.

STEAL CABLE…… NO ONE calls it ‘wire rope’

Steal?

Steel!

😂

https://southeastrigging.com/difference-of-wire-rope-and-cable-rope/

They’re different. You can make wire rope out of steel cable https://southeastrigging.com/difference-of-wire-rope-and-cable-rope/

Consider you can’t even spell steel correctly i doubt you are an expert … neither am I but I have used wire rope that contains no steel.

My grounding wire is constructed the exact same way, it’s a wire rope made completely out of copper strands

Not true. Wire rope is the proper name for multi-stranded steel cable.

Wire rope. My husband worked as a strander in a wire rope mill for over a decade.

Cable is not able to go around a sheave continuously. Wire rope can.

Quite a few people do actually, I guess it depends whether you use it professionally And Maybe what industry you’re in?.

It’s illegal to steal cable in most jurisdictions.

I worked offshore for ten years and it was always wire rope. We also used the above nautical terms for parts of line, but it was understood that you never saddled a dead horse. I never wanted my friends and coworkers to end up at the bottom of the sea unless they chose to be there. If you really want to abuse wire rope, go look up a “Molly Hogan” splice.

I wonder if putting the aluminium (yes, I’m Europeam) sheaths as an extra protection over the ends won’t harm the cable in the long term, by reduction of dissimilar metals. It will eat the aluminium first, but it might slightly alter the steel and thus compromise it’s strength.

Also: What’s wrong with a good old cable splice?

I was thinking if the aluminum crimps are safe enough. they seem to be ubiquitous, but i remember aluminum wires geting loose in brass screw terminals in matter of couple years. sounds very sketchy from climbing gear.

BTW i am so excited to see HowNot2 featured on Hackaday. I’ve never expected those interrest bubbles of mine (sport and nerding) to meet, but since they are sport nerds, i guess it makes sense they got here :-)

We’re everywhere :) I love HowNot2’s videos.

I discovered hownot2 i think during the pandemic, and am quite hooked. They give an interesting insight into the climbing world. Seems like a nice social bubble of nice people!

I haven’t ever climbed more than a stair, so this insight into another universe is really nice.

I do a fair bit of off-roading and in that field almost everyone has moved to synthetic ropes now for safety & ease of handling – they are more fragile especially with abrasion but they are just so much nicer to use, and these days there’s not much cost penalty either.

The cheap Chinese winches still come with wire rope but those are usually broken after the first encounter with muddy water anyway.